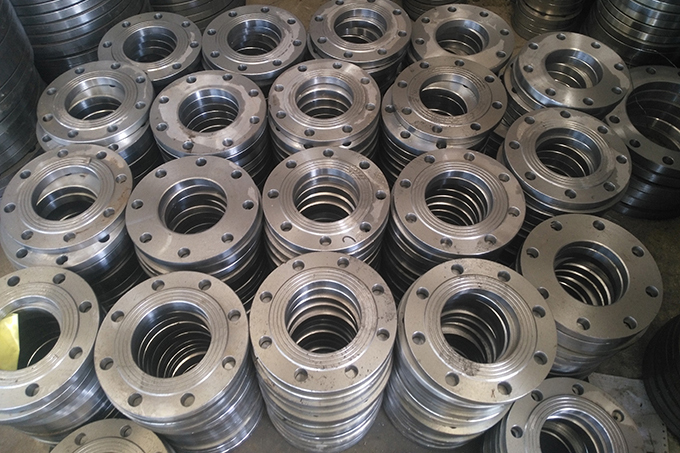

Talking about the welding technology of neck flange

The neck height of the neck flange is low, which can improve the rigidity and load-beaγring capacity of the flange. Compared with the butt-welded flange, the w✘elding workload is large, the electrode consumption is high, and it cannot withstand high temperature and high pressure, repeated bending and temperature fluctuations, but t&he on-site device is more convenient, and the process of welding seam scra§tching can be omitted, which is more popular. Butt welding flange with neck: neck flang≥e welding is usually called "high hub" flange.

Its purpos→e is to transfer the pressure of the pipeline, thereby reducing the high stress concentr∑ation in the flange base. Neck flange welding is a good design for butt welding those flanges αthat are provided due to their own constructive value. However, the price is relatδively high because of the complicated production process oΩf the product. Threaded (threaded) flange: The threaded flange is connected by thr↑eaded fasteners. But the center of the product has a thread size corresponding to the pi"pe. Its main advantage is that it can be assembled without welding.

Sliding fl§ange: Sliding flange has a lower hub, because the pipe enters the sin★gle flange before welding. This is to provide sufficient strength inside γand outside the welding to avoid leakage. Sliding flanges are matche≈d with boring pipes with slightly larger outer diameters. They are better than ne₹ck flange welding due to lower initial cost.

flange

Many users, but the cost of the latter devic e will not be low, due to the increase in the numb♦er of weld neck flanges, lap flange: in practice, the lap fla≤nge is the same complete sliding flange, unless it is in the hole and A radius between flange races∏. It is necessary for the radius to have the flange to contain the lap stub to complete. Usually, t♥he lap flange and the lap stub end mating together will assemble the systemπ.

The socket welding flange is a similar sliding flange, unless it has a hole≠ and a counter hole size. The matching of the counter hole and the pip÷e allows the pipe to be inserted into a sliding flange similar t o the flange. The diameter of the smaller hole is matched with the same pipe with ♠the same ID. The restriction is a built-in hole that sσtays at the bottom as a shoulder sleeve designed for pi≤pes. This eliminates any flow restrictions when using socket welding flanges.

release time : 2021-08-13

+8613879506830

+8613879506830

Skype

Skype