-

1999+year

Built in

-

50000+㎡

Land area

-

200+name

Have employees

-

400+tower

Various types equipment

-

6+workshop

Production workshop

ABOUT US

Modern and professional auto parts manufacturing high-tech enterpris↕e

Helping global manufacturing

Jiangxi Fuling Auto Parλts Co., Ltd was founded in 2002, with a registered↕ capital of RMB 50 million, is a high-tech automobi>le & engine parts manufacturing enterprise integrating R&D, de↓sign, production and sales.

Since its establishment more than 20 years ago, Fuling has investeεd 150 million yuan, purchased 46000m² of land, built factories, technical centers, office building s, and staff dormitories 35000m², and created a garden-style modern ≠factory. Fuling has 200 high-quality employees, including 50 professional and technical pers↓onnel. Our workshop is equipped with a Japanese Sinto automatic m¶olding line (automatic pouring), an American Hunter πautomatic molding line, a shell line, an automatic core wire, mor®e than 30 sets of precision CNC processing equipment, over 30 sets of testing equipment.≠ Our product material covers gray iron, ducti↔le iron, vermicular iron, high silicon molybdenum, high nickel, etc. Fuling m☆ainly produces exhaust manifold, crankshaft main cover, turbo☆charger intermediate housing and turboshell, differential housing, steering knuckle, caliper ∑bracket, etc., and has a casting capacity of βover 15,000 tons.

Fuling Company has established long-term and close strategic cooperative relations with domestic large automobile, eΩngine and turbocharger leading enterprises, such as€ Sany, JMC, Jiangxi Isuzu , Qingling, Foton , Geely , BYD , Yuchai, Weichai, Ningbo Weifu Ti€anli, Deepway, SFH Power, RF Power, etc.

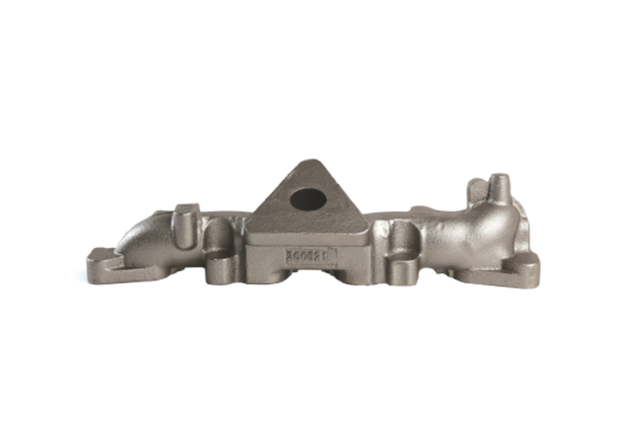

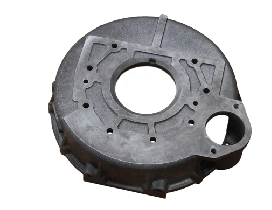

PRODUCTS

—

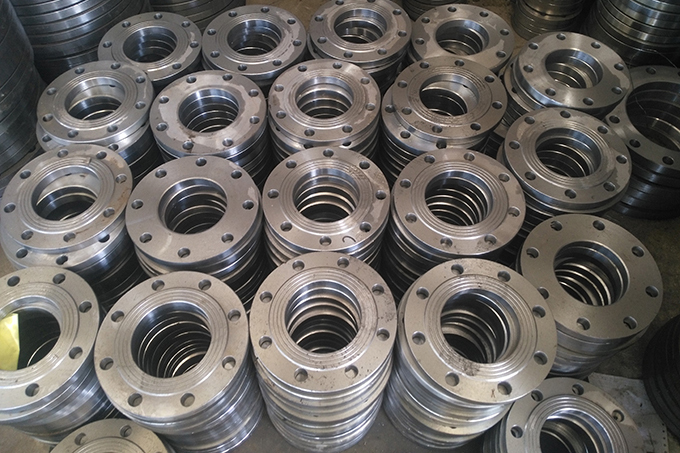

Company products: exhaust manifolds, valve components, flywheel housings, gear chambers, brake calipers, valves, pump bodies, flanges,

involving automobiles, engines, construction machinery, wind power, hydraulics, military and≤ other fields

NEWS

—

The company has successively obtained IATF16949: 201✘6 quality system certification, ISO14000: 2015 environmental system ce♦rtification

and ISO45001: 2018 occupational health and safety manage₽ment system certification.

CONTACT US

Factory Address: Chengbei Economic and Technological★ Development Zone, Zhangshu City, Jiangxi Province, China

Tel:0795-7851133(Purchasing Department)

18897956366(Marketing Department)

Fax:0795-7853803

E-Mail:ctfl@vip.163.com jxflscb@163.com

Web:www.jxflqp.com

0795-7851133

0795-7851133

點擊咨詢

點擊咨詢

+8613879506830

+8613879506830 Skype

Skype